Tier 4 Engine Technologies

Understanding How They Work, plus Maintenance Tips

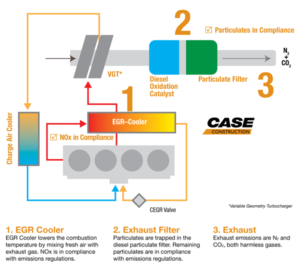

CEGR – Cooled Exhaust Gas Recirculation

In CASE C Series Excavators and N Series Loader Backhoes

Diesel Particulate Filter Tips

Performance

- The DPF works most efficiently at full throttle, as the engine is burning cleaner while the rpm is constant.

Maintenance

- The DPF is designed to last for a minimum of 3,000 – 3,500 hours.

- The filter is positioned for easy access on all machines to facilitate service when required.

- The DPF is cleaned using a regeneration process, which occurs while the filter is on the machine.

- Low ash CJ-4 engine oil is required.

Operation

- There are no changes needed in general equipment operation.

- Only use ultra-low sulfur fuel.

SCR – Selective Catalytics Reduction

In CASE F Series Wheel Loaders

Diesel Exhaust Fluid Tips

Maintenance

- Refilling the DEF tank can be incorporated into a regular maintenance or refueling routine.

- Always be proactive about checking DEF levels.

- Change supply module filters at required intervals.

- Low ash CJ-4 engine oil is not required but can be used.

Performance

- SCR system is separate from the main engine function and does not affect horsepower or torque.

- RSCR technology is highly efficient and reduces fuel consumption.

Operation

- Each machine includes a DEF gauge and a warning signal when DEF level is low, similar to a fuel gauge.

- Only use ultra-low sulfur fuel.

Purchasing DEF

- DEF is available in four container sizes from CASE: 2.5 gallon, 55 gallon drum, 275 or 330 gallon totes.